Overview

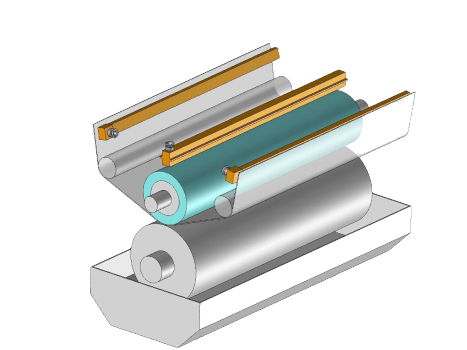

Since gravure prints from depressed, ink-filled cells engraved in the surface of a metal cylinder, a recurring problem is the incomplete transfer of ink from the cells to the substrate passing above it. As a result, printing defects such as snowflaking, skips, and other voids and missing halftone dots tend to recur.

Electrostatic Assists (ESA) alleviates this by generating an electric field in the region of the nip between the impression roller and the gravure cylinder (where ink transfer takes place) so that the ink is pulled electrostatically onto the substrate.

Applicable for use on plastic films, paper and textiles.

Our Solutions

Heliofurn ESA System

- Reduces line pressure by up to 50%

- Reduces gravure depth by up to 40%

- Polarisation (spread) of the ink can be set in a range from 0-100%

- Easy to install

- Requires close to no maintenance

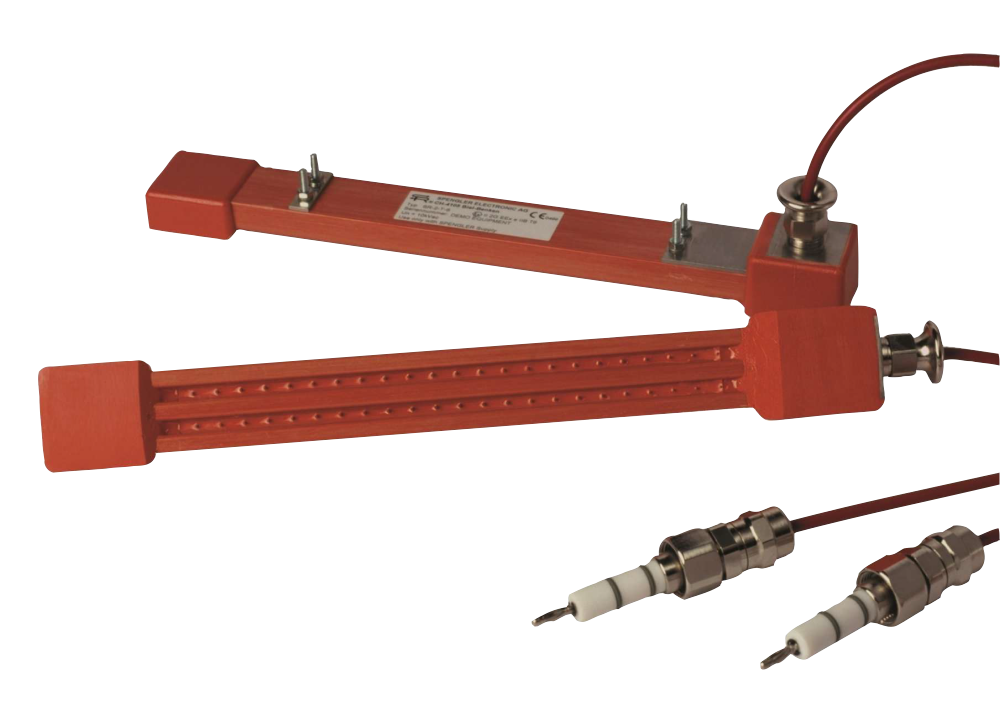

AC Ionizers

Our AC ionizers cycle producing negative charged ions and positive charged ions from the same emitter pin.

- Eliminates static electricity at a distance of 20 to 30mm.

- Suitable for high-speed machines.

- For discharging any kind of web or textile.

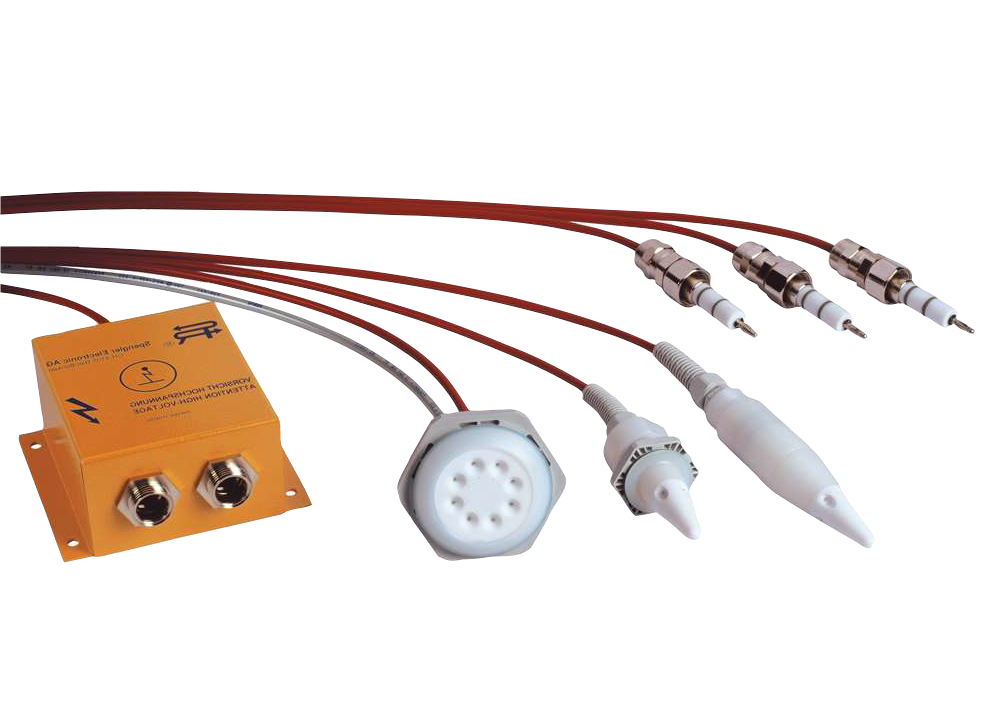

DC Ionizers

Our DC ionizers produce positive charged ions and negative charged ions using different emitter pins.

- Eliminates static electricity at a distance of 2500mm.

- Ideal for rewinders

Proudly supplied by

For more than 50 years, the team of experts at Spengler has been researching, developing and producing electrostatic applications using innovative technology for practical, user-friendly solutions.

Visit websiteLooking to purchase our products or have any other questions?